Tackle High-Volume Projects Confidently and Efficiently

Accelerated speed to market with Neff’s cutting-edge printing solutions.

At Neff, we understand that large food companies and agencies alike need quick, high-quality samples to stay ahead in today’s competitive marketplace. Weensureour clients receive rapid, top-notch packaging solutions while meeting tight deadlines. Now, with our newly installed Landa S11 printer, we’re more prepared than ever to help you get your products out faster.

Why Neff?

- Quick Turnaround for Large Projects

Our enhanced capacity means we can take on multiple large-scale jobs simultaneously, perfect for tight timelines and fast-moving campaigns.

- Superior Print Quality

The Landa S11’s advanced technology delivers best-in-class color consistency, allowing your packaging to stand out on shelves and in sales presentations.

- Media Versatility

From coated and uncoated paper to carton board, we can handle the materials you need to bring your packaging vision to life.

- Digital Flexibility

Seamless customization and variable data printing allow you to adapt quickly, whether you’re running small test batches or full-scale production.

- Speed to Market

Faster print speeds reduce lead times and bottlenecks, ensuring you can get samples into agencies’ hands sooner—and your products into consumers’ carts more quickly.

We’re here to help you manage diverse and complex projects efficiently, all while maintaining the quality your brand deserves.

Ready to discuss your next project?

Increasing Our Capacity to Better Serve You

Not only is Neff doubling its production capacity, but we are also elevating our quality standards.

Taking on Large & Diverse Projects Just Got Easier

Neff has recently installed a brand new Landa S11 printer, marking a significant milestone in our production capabilities. This high-performance printer allows us to handle a larger volume of projects simultaneously, enabling us to manage multiple large-scale projects with greater efficiency. As a result, we can take on more complex and diverse printing tasks, ensuring that we meet the increasing demands of our clients without compromising on quality. This investment is a testament to Neff's ongoing commitment to future growth and innovation. By continuously upgrading our technology and enhancing our capabilities, we aim to provide superior service and support to our valued customers, meeting their needs both now and in the future.

Unleash Your Creativity

- Digital flexibility

- Superior quality

- Faster speed to print

- Best-in-class color consistency

- Media versatility – all coated and uncoated off-the-shelf paper and carton board

The enhanced capacity means we can efficiently manage multiple large-scale projects at once, significantly reducing bottlenecks in our workflow. This not only improves our overall productivity but also ensures that we can meet tight deadlines with greater ease. Our customers will benefit from quicker turnaround times, receiving their products faster than ever before.

In addition to speed, the Landa S11's advanced technology provides superior print quality, which further enhances the customer experience. We are excited about the opportunities this brings and look forward to delivering even better service to our valued clients.

Ready to discuss your next project?

Wishing You Merry Christmas and a Happy New Year!

As 2024 comes to a close, we want to extend our gratitude to our valued customers for trusting us with your carton printing and packaging needs. Your partnership has been the cornerstone of our success, and we’re excited to continue innovating and supporting your business goals in 2025. Here’s to another year of growth and collaboration.

If you’re planning a new project for 2025, we’re here to help bring your vision to life. Whether it’s choosing the right printing solutions or customizing inks for unique packaging needs, our team is ready to support you every step of the way.

We will be closed 12/24, 12/25, 12/31, and 1/1.

Neff Packaging Honored with Prestigious G7 Master Qualification

Consistent, reliable results on every print job, backed by industry-leading standards.

elivery Unmatched Precision and Consistency

Neff Packaging has been honored with the prestigious G7 Master Qualification from the Printing United Alliance. We're now part of an elite group of companies recognized globally for our ability deliver superior results that not only meet but exceed the industry's highest standards.

How Did We Achieve This?

Neff Packaging is proud to be the first to earn the prestigious G7 Master Qualification for its digital printing press. This achievement reflects our commitment to excellence in color management and ensures consistent, high-quality printing across all our operations.

To achieve this, we calibrated our printing processes according to G7 standards, ensuring precise color consistency and alignment across various jobs. By working with a Certified G7 Expert, Neff Packaging went through testing and verification, proving our ability to meet the highest industry standards for color accuracy.

What Does This Mean for Our Clients?

You can now request projects with greater confidence, knowing that every job handled by Neff Packaging meets the highest standards of quality control. Clients can expect unmatched precision, reliability, and consistency in every project, with enhanced efficiency and reduced waste.

Increase Flexibility in Design: short to medium run custom diecut and digital print cartons available from our Color Sprint Packaging division.

Ready to discuss your next project?

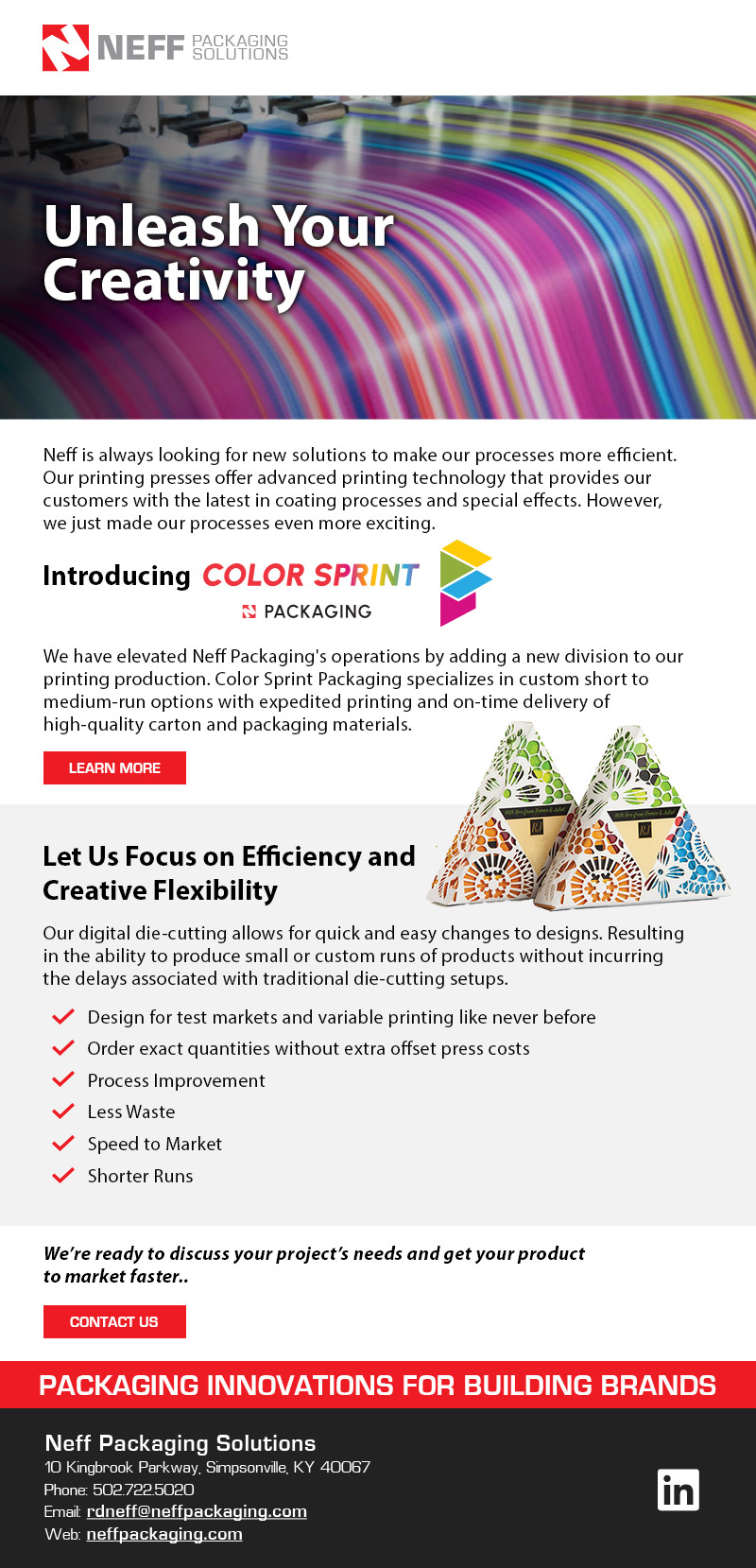

Unleash Your Creativity

Neff is always looking for new solutions to make our processes more efficient. Our printing presses offer advanced printing technology that provides our customers with the latest in coating processes and special effects. However, we just made our processes even more exciting.

Introducing Color Sprint Packaging

We have elevated Neff Packaging's operations by adding a new division to our printing production. Color Sprint Packaging specializes in custom short to medium-run options with expedited printing and on-time delivery of high- quality carton and packaging materials.

Let Us Focus on Efficiency and Creative Flexibility

Our digital die-cutting allows for quick and easy changes to designs. Resulting in the ability to produce small or custom runs of products without incurring the delays associated with traditional die-cutting setups.

- Design for test markets and variable printing like never before

- Order exact quantities without extra offset press cost’s

- Process Improvement

- Less Waste

- Speed to Market

- Shorter Runs

We're ready to discuss your project's needs and get your product to market faster..

Wishing You Merry Christmas

and a Happy New Year

We will be closed 12/25, 12/26, 12/29 and 1/1 in observance of the Holidays

Commitment Beyond Certifications:

Packaging for the Planet

Environmentally conscious shoppers increasingly seek brands emphasizing environmentally friendly practices, making sustainable packaging essential for business success.

Neff Packaging Solutions has a historically strong commitment to environmental sustainability practices because practices that are good for the environment are good for business. “A key component to recycling is understanding paperboard and its environmental impact. Landfills represent a loss to our economy and our earth because everything thrown into a landfill does not properly return to the system. In a nutshell, landfill waste is a waste of resources.” - Jim Younkin, Vice President of Operations for Neff Packaging Solutions

Neff Packaging Solutions proudly holds several industry-leading certifications showcasing our dedication to our clients and the planet.

- FSC (Forest Stewardship Council) – Our products originate from responsibly managed forests. FSC-certified packaging is a positive choice for the environment and its diverse ecosystems.

- ISO – A testament to our relentless pursuit of excellence, emphasizing quality and efficiency in our operations.

- G7 Recertification – Recognition of our dedication to consistent color reproduction and print quality means we ensure your brand’s visual integrity.

- GMI (Graphic Measures International) – We assure our partners of our commitment to unsurpassed print and packaging solutions, marked by rigorous quality control measures.

- cGMP (current Good Manufacturing Practices) – We adhere to top-tier manufacturing processes, emphasizing safety and sustainability

Neff Packaging Solutions is prepared for the future, grounded in proven practices and meaningful certifications. Join us in leading the sustainable future of packaging.

Wishing Everyone Merry Christmas and Happy New Year

Neff Packaging will be closed on December 19th for Annual Safety Training for all employees.

In observance of the holidays, we will be closed December 23rd, 26th, 30th and January 2nd.

Moving Press Checks from Our Facility to Your Home

Thanks to the unprecedented times we're living in, businesses are doing more and more things virtually than ever before. The printing industry is no exception.

Press checks are a part of life for all of us, but even that tried-and-true quality control process has gone virtual.

Virtual Press Checks Start Well Before the Actual Press Check

Succeeding in the virtual space means being prepared for anything. From simple package design to complex layouts, it's important to establish a strong preapproval process and quality assurance testing well before a virtual press check. This can include assembling an experienced team for a series of internal meetings and "pre-game" consultations with clients to set clear expectations and timelines. It also makes certain that everyone is on the same page throughout the entire life cycle of your project.

Virtual Press Checks can Save Everyone Time and Expenses

Communication is vital throughout the entire process. Whether it's exchanging photos of the press sheets or establishing an approval protocol, keeping everyone informed is the key to a successful printing job.

Virtual press checks are likely here to stay, which can be great for your business. They take less time to complete than an on-site press check, and you can save on your overall costs.

Neff is here for you through every virtual step to exceed your expectations.

Consumers rank packaging higher when it lives up to the excitement of the product.

How Does Your Packaging Rank?

We know that many consumers rank a product's packaging, almost equal to the brand. At Neff, we specialize in providing the "surprise factor" that today's shoppers require.

Neff's state-of-the-art printing capabilities are unmatched in North America. We provide advanced printing technologies including soft touches, high gloss coatings, foils and other special effects that make opening your package...extra special.

Additionally, our presses produce spectacular effects without expensive tooling/dies for short runs—making production of beautiful packages for your special promotion or test market—sensational and at the same time affordable.

Our in-house capabilities provide the widest array of packaging enhancements including:

- Specialty Inks & Textured Effects

- Cold Foil & Foil Stamping

- Embossing

- Die Cutting, Gluing, Tipping & Labeling

- Security Options

Neff delivers the advanced effects your package requires...

to outrank all the others!

Wishing Everyone Merry Christmas

& Happy New Year

Neff Packaging will be closed in observance of the holidays December 24th, 25th, 31st and January 1st.

Packaging Innovations That Builds Brands Michter's Commemorative Packaging

Neff was selected to develop and manufacture new folding cartons to commemorate Michter's Fort Nelson Distillery. This important brand dates to 1753 and claims to be America's first whiskey company.

Challenge

The original art specifications were problematic: metalized polyester with solid bleach sulphate that required: two white inks, CMYK, a match yellow to create copper, one background color, two coatings. These specifications would produce an expensive package that would not be environmentally friendly. The Neff design team went to work to develop a sophisticated package that was both recyclable and cost effective.

Solution

To create a more sustainable solution, we tested cold foil as a replacement for the polyester. Cold foil is applied during the printing process and is adhered to the paperboard with glue. When recycled, the foil separates from paperboard during the deinking process, is burned for fuel, and does not go into the waste stream. Cold foil can be applied to just the areas needed for foil blocking.

Our solution saved Michter's money while reducing its impact on the environment. Using cold foil allowed the elimination of two colors from the artwork, which also eliminated the cost of two inks and two plates. In addition to the costs savings, it also reduced time during prepress.

When your product needs a technically precise package to present your brand that is cost effective and environmentally friendly – accept nothing less.

In a world of crisis,

how did your BCP plan hold up?

Neff Packaging Solutions can help.

Is your Business Continuity Plan ready to meet today's challenges? Neff Packaging Solutions has the capacity and experience to satisfy your BCP requirements. This is especially critical in today's environment where safety and consistency cannot be overlooked in any consumer market.

Additionally, our in-house resources, including state-of-the-art high performing presses and our new Structural & Design Innovation Center have long been the envy of the industry. Neff's investments on the production floor, complete with specialized capabilities, have been instrumental in achieving speed to market and sales-winning packaging.

Neff In-House Advantages:

- Safety with verifiable accuracy

- Quality ISO-9001-2015 certified, cGMP, FSC, G-7 Master printer, GMI, Ecovidas Corporate responsibility, Disney Social responsibility

- Patented Solutions that increase sales at less cost

- Speed to handle unplanned demands from customers

- Designs/Materials/Processes that increase sales

From high-speed printing with complete color management to specialty inks, coatings, textured effects, and security features – Neff offers it all in-house for fast and continuous deliveries of your packaging. We invite you to our facility to see what others have called 'The fastest and most advanced printing facility in the US.

COVID-19 Announcement

We are in unprecedented times. The spread of COVID-19 has disrupted every aspect of our lives, and things are changing quickly. I wanted to provide an update on the actions of Neff Packaging Solutions is taking to safeguard the health and wellbeing of our customers, our team and their families.

We have taken the following preventive measures: restricting non essential business travel; implementing audio and video conferencing wherever possible; encouraging our employees to wash their hands, wiping down door handles and surfaces, social distancing in the working environment and doing all we can to stay updated on COVID-19 developments and best practices recommended by the CDC.

From a business perspective, Neff Packaging Solutions is currently operating with no disruption. We continue to serve our customers as we always have. We're actively monitoring the situation and our supply change.

Jim Younkin

Chief Operating Officer

Neff Packaging Solutions

Neff Packaging

Solving Difficult Packaging Challenges Since 1918

WE'VE BEEN PROVIDING INNOVATIVE PACKAGING SOLUTIONS THAT REDUCE WASTE, COST, AND TIME... GUARANTEED.

Neff Packaging Solutions is recognized as one of the most technologically advanced folding carton plants in North American and provides innovative custom packaging solutions for many of the nation's top Branded Consumer Product companies. Our operational effectiveness and technology-based strategies allow us to develop creative solutions that meet the specific needs of our customers. We solve difficult challenges with an approach that is both lean and sustainable.

We design and manufacture specialty paperboard packaging for branded consumer product companies, including bonus packs, club store, consumer sampling, professional packaging, counter-top displays, blister cards, foil packaging, and other kinds of specialty packaging material.

Neff Product offerings span industries from health care, luxury goods, tobacco & spirits, promotional and consumer sampling.

Our strength is in finding creative solutions to customer problems that create a better package at a better cost.

Neff Packaging, Delivering Results!

- Trusted For Consistent Repeatability

- The Fastest Production Facility In The Nation

- Known For The Perfect Package

- Advanced Direct Mail Sampling Options

- Verifiable Accuracy & Safety In Consumer Markets

Learn More.

Award Winning PackAging Innovation Generates Business Results & Wins Awards

Neff Packaging Solutions is focused on solving difficult challenges with innovative packaging ideas and this approach also wins awards. Previously Neff was recognized as a leading technologically advanced folding carton plant in North America.

In December, they were recognized at the 2019 New Jersey Packaging Executives Club 41st Annual Package of the Year Award in the area of Technical Merit for production of Clarisonic Holiday 2018 packaging for Veritiv Corporation.

At Neff technical know-how includes a packaging process that is reliable, repeatable, lean, and sustainable. We design and manufacture specialty paperboard packaging for pharmaceutical, luxury goods, health care, promotional, and consumer sampling products using specialty coatings, printing, embossing and holographic production techniques to provide our clients with the brand enhancing packaging to help them win the "First Moment of Truth" at retail.

Neff's campus in Simpsonville, Kentucky includes 122,000 square feet of state-of-the-art manufacturing, an innovation center for structure and design, and 80,000 square feet of space for Vendor Managed inventory. Our innovative packaging solutions will reward you with increased sales.

Learn More.

Delivering Results

Advanced direct mail & retail sampling options designed to increase sales at less cost.

Finally, a sample mailer that meets postal regulations, mails at low cost, and has a large billboard space for printing!

Advantages:

- USPS Approved for Sachet Mailing

- Mails at Automated Letter Rate

- $0.22–0.27 (depending on mailing list)

- Large Billboard Space

- outside and inside printing opportunities

- couponing available

- Secure Sample Section

- ideal for liquids, gels, pastes, and powders

- Recyclable Board & Film

- Easy to Open

- Many Sizes

- U.S. Patent No. #10065765 and #RE46998

Unlike most packets that mail as automated flats at 50 cents each, SafeMailer™ is mailed at 25 cents each. That's a postage savings of $250,000 for a mailing of one million samples!

Delivering Savings with SafeMailer™

Learn More.

Neff Packaging Solutions recently installed a Scodix Ultra Pro™ digital press with a Scodix Foil Station™ to create specialty boxes with high-end luxury finishes. To experience the premium effects of this press, visit neffpackaging.com to request a sample (USA only).

In conventional processes, embossing requires a 2-step die and a separate die cutting pass. Our new Scodix press produces the desired effects without time consuming and expensive tooling and dies for short runs.

This digital process allows Neff to add high gloss, foil, and selective spot varnish enhancements in-house in a single pass. Consumer packaged goods industries including cosmetics, perfume, spirits, confections, and health care will benefit greatly from this capability.

Enhanced Effects for CPG Packaging:

- Digital UV Effects

- Digital Foil Stamping

- Digital Spot Varnish

- Digital Braille

To request a box sample,

complete our order form.

You are invited to our Open House at the Penn Club during LUXE Pack New York 2017

Neff will be presenting new packaging innovations with our Scodix press at our open house at the Penn Club during LUXE Pack NY.

Join us for cocktails, appetizers, and conversation.

RSVP Now.

Visit Neff Packaging Solutions at the

"Packaging That Sells Conference"

October 12-14 in Chicago!

The Drake

Chicago, IL

More Information.

Neff Introduces SafeMailer™!

Finally, a sample mailer that meets postal regulations, mails at low cost, and has a large billboard space for printing!

Learn more here: Consumer Sampling.